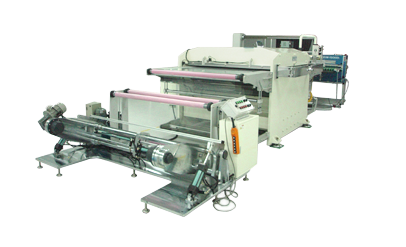

SL-ROLL PRESS

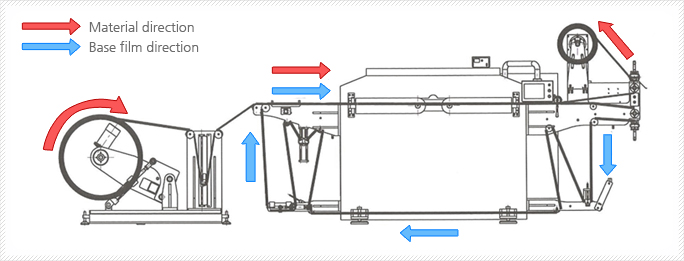

Material direction

Specification

| Specification | SI-1350*1350 | SI-1500*1500 | SI-1500*2000 | SI-1650*1650 | SI-1650*1800 |

|---|---|---|---|---|---|

| Voltage | 3-phase 220/380V |

3-phase 220/380V |

3-phase 220/380V |

3-phase 220/380V |

3-phase 220/380V |

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz |

| Current | MAX: 40A | MAX: 40A | MAX: 40A | MAX: 40A | MAX: 40A |

| MIN: 10A | MIN: 10A | MIN: 10A | MIN: 10A | MIN: 10A | |

| Spindle motor | AC 220V | AC 220V | AC 220V | AC 220V | AC 220V |

| 10Hp 7.5Kw | 10Hp 7.5Kw | 10Hp 7.5Kw | 10Hp 7.5Kw | 10Hp 7.5Kw | |

| Press base plate size | 1350mm | 1500mm | 1500 * 2000mm | 1650mm | 1650 * 1800mm |

| Max. feeding | 1350mm | 1500mm | 2000mm | 1650mm | 1650mm |

| Spindle rotary speed |

100RPM | 100RPM | 100RPM | 100RPM | 100RPM |

| main pneumatic | 5~7Kgf/㎠ | 5~7Kgf/㎠ | 5~7Kgf/㎠ | 5~7Kgf/㎠ | 5~7Kgf/㎠ |

| Feeding speed | 1.5m/Min | 1.5m/Min | 1.5m/Min | 1.5m/Min | 1.5m/Min |

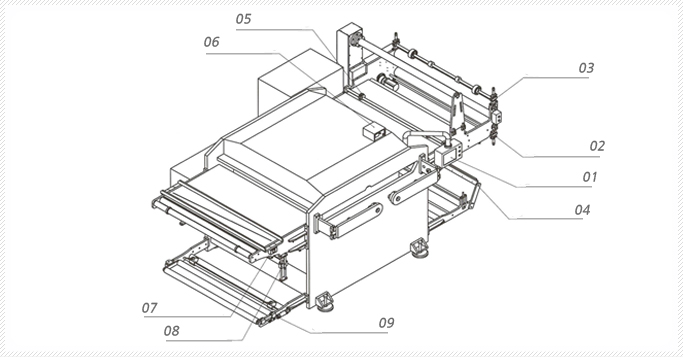

Components of the main body and material machine

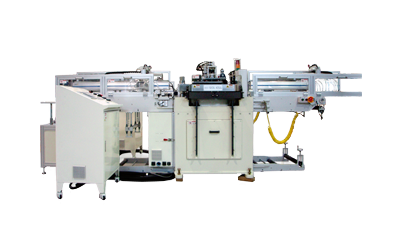

Components of main body

| No. | Name | Description |

|---|---|---|

| 1 | Main body operation screen | This touch screen includes overall contents for equipment operation. |

| 2 | Bottom urethane | It is a tool for transporting the base film, and a cylinder is fixed on each side and a roller in the middle. |

| 3 | Top urethane | It is a tool for transporting the material scrap, and a cylinder is fixed on each side and a roller in the middle in order to collect scraps with air chuck. |

| 4 | Foreign substance remover for base film | By unwinding the bar fixed with a bolt, it is fixed with a film or wiper and then removes foreign substances from the base film. |

| 5 | Handle bar | It separates the product and scraps by using a urethane roller on the contacted area of base film and material, and is controlled by the handle bolt on the urethane roller. |

| 6 | Scrap tension controller | It controls the tension when the scraps are wound too much by the air chuck. By rotating the manual volume, it increases the voltage. |

| 7 | Base film fixer | When replacing the base film, it fixes it to adjust the either sides of the base film by using the cylinder and finishing with a tape. |

| 8 | Weight roller | By fitting a heavy roller to prevent the base film from sagging, it transports the base film closely put with the material. |

| 9 | Base film transportation device | The part that transports the base film in one direction is controlled by a cylinder so that, when the limit switch is touched, the direction is changed to move the base film to the opposite direction. |

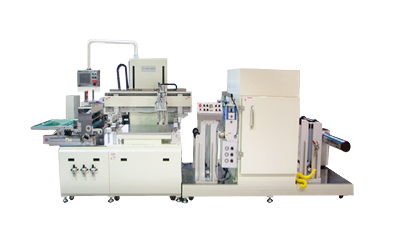

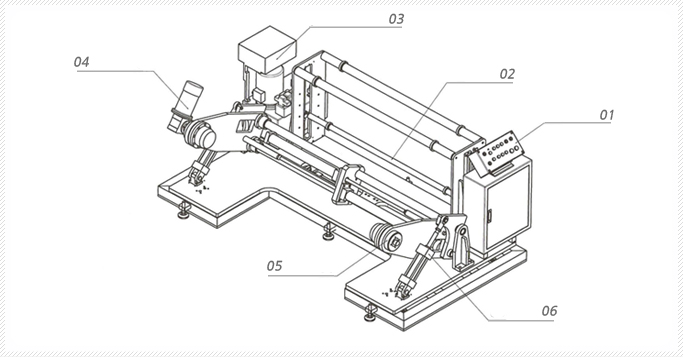

Components of material machine

| No. | Name | Description |

|---|---|---|

| 1 | Machine operation board |

It is composed of switches to fasten, loosen, and move the machine in four directions with a separate remote switch. |

| 2 | Top/bottom moving roller | This roller controls the speed of the material and moves up and down. It is controlled by stop/ low speed/ high speed/ and emergency stop sensor, to control the winding of the material. |

| 3 | Hydraulic unit | This part controls each hydraulic cylinder, and operates them by sending oil to the hydraulic pump. |

| 4 | Motor | This part controls winding of the material at high or low speed, and can control in the original or reverse direction by using sensor as it is connected to the a paper tube of the material. |

| 5 | A paper tube shaft | It holds the a paper tube of both sides on the material. A bearing is included on the inside and outside so that the material can be hung easily for easy rotation. |

| 6 | Up/down cylinder | When moving the material by truck, the up and down movement of the cylinder allows the material to be easily moved regardless of its external diameter. |